advantages of using printed circuit board assembly manufacturer

Printed circuit board assembly (PCBA) manufacturers offer a range of advantages that make them indispensable partners in the electronics industry. These advantages stem from their expertise, specialized equipment, and commitment to quality, enabling efficient and reliable production of electronic assemblies for various applications.

One of the primary advantages of using PCBA manufacturers is their expertise and experience in electronics manufacturing. These companies employ skilled engineers, technicians, and operators who possess in-depth knowledge of PCB design, assembly processes, and industry standards. Their expertise allows them to navigate complex design requirements, optimize manufacturing processes, and troubleshoot issues effectively, ensuring the quality and reliability of the final product.

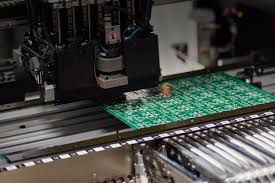

Additionally, printed circuit board assembly manufacturer invest in state-of-the-art equipment and facilities to support efficient and high-quality production. Advanced assembly equipment, such as pick-and-place machines, soldering reflow ovens, and automated inspection systems, enables precise component placement, soldering, and quality control. These capabilities ensure consistent results, minimize errors, and reduce production lead times, allowing for faster time-to-market for electronic products.

What are the advantages of using printed circuit board assembly manufacturer?

Moreover, partnering with PCBA manufacturers offers scalability and flexibility in production. These companies can accommodate varying production volumes, from small prototype runs to large-scale production batches, to meet the needs of their clients. By leveraging economies of scale and efficient production processes, PCBA manufacturers can offer competitive pricing and cost-effective solutions for electronic assembly projects.

Furthermore, PCBA manufacturers provide access to a wide range of materials, components, and technologies to suit diverse application requirements. Whether it’s sourcing specialized components, selecting suitable substrates, or integrating advanced features like wireless connectivity or sensors, these manufacturers have the expertise and resources to address unique project needs. This access to a comprehensive supply chain streamlines procurement processes and ensures availability of components for timely production.

Another advantage of using PCBA manufacturers is quality assurance and compliance with industry standards and regulations. These companies adhere to rigorous quality control processes and inspection protocols throughout the manufacturing process to detect and prevent defects. By implementing quality management systems such as ISO 9001 and adhering to industry standards like IPC-A-610 for soldering and assembly, PCBA manufacturers ensure that electronic assemblies meet or exceed quality requirements and regulatory standards.

Moreover, partnering with PCBA manufacturers can result in improved product reliability and performance. Through careful design optimization, material selection, and assembly techniques, these companies can enhance the durability, thermal management, and electrical characteristics of electronic assemblies. Robust testing and validation procedures further validate the integrity and functionality of the products, reducing the risk of field failures and warranty claims.

Additionally, outsourcing PCB assembly to specialized manufacturers allows original equipment manufacturers (OEMs) to focus on their core competencies and strategic priorities. By offloading manufacturing tasks to external partners, OEMs can free up resources, reduce overhead costs, and streamline their operations. This collaborative approach fosters innovation, accelerates time-to-market, and enhances competitiveness in the fast-paced electronics industry.

In conclusion, the advantages of using printed circuit board assembly manufacturers are numerous and impactful for electronic product development and manufacturing. From expertise and specialized equipment to scalability, quality assurance, and strategic partnerships, these companies play a critical role in driving innovation and efficiency in the electronics supply chain. By leveraging the capabilities of PCBA manufacturers, businesses can realize their product goals, achieve market success, and deliver value to customers in an ever-evolving technological landscape.